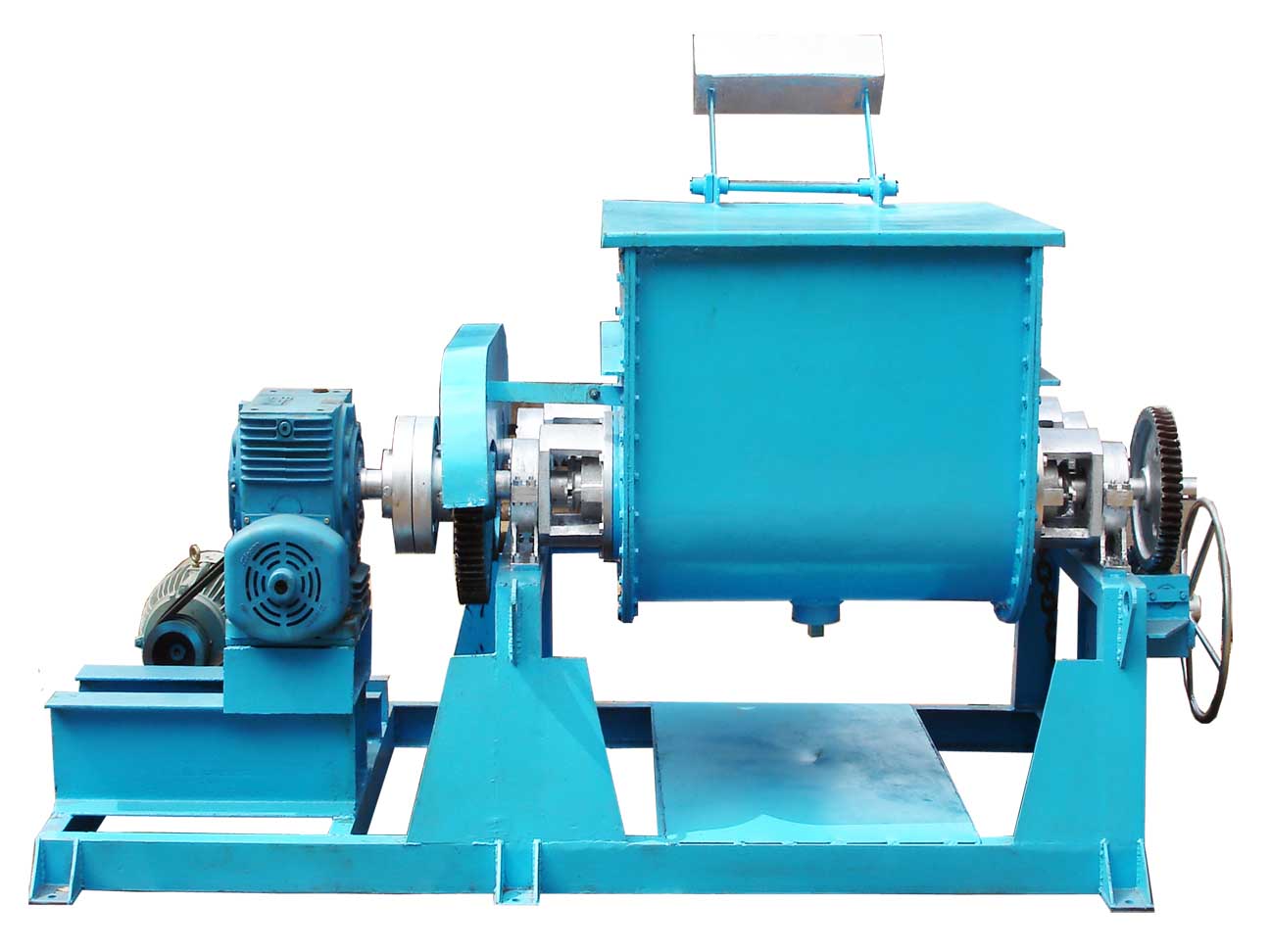

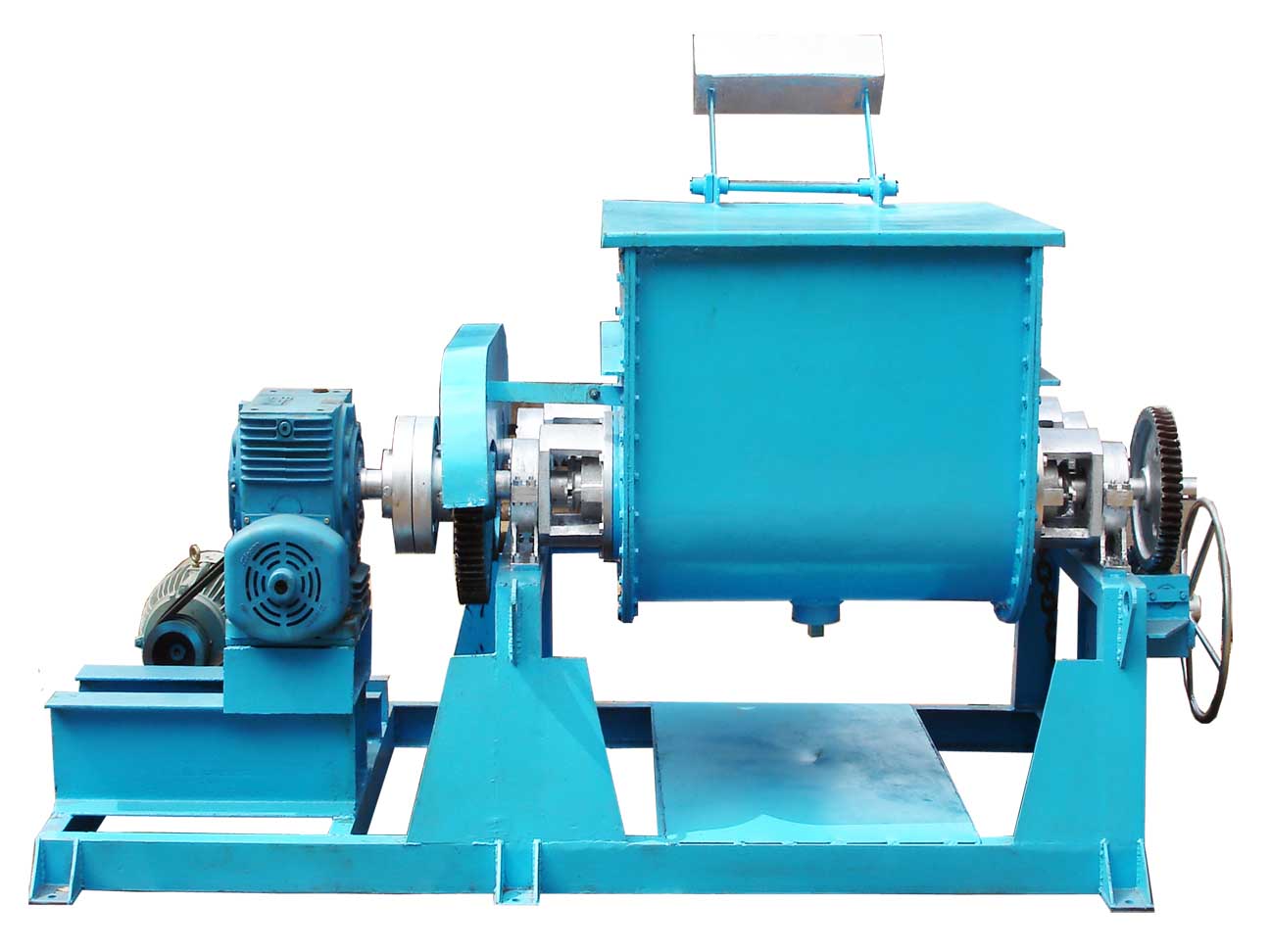

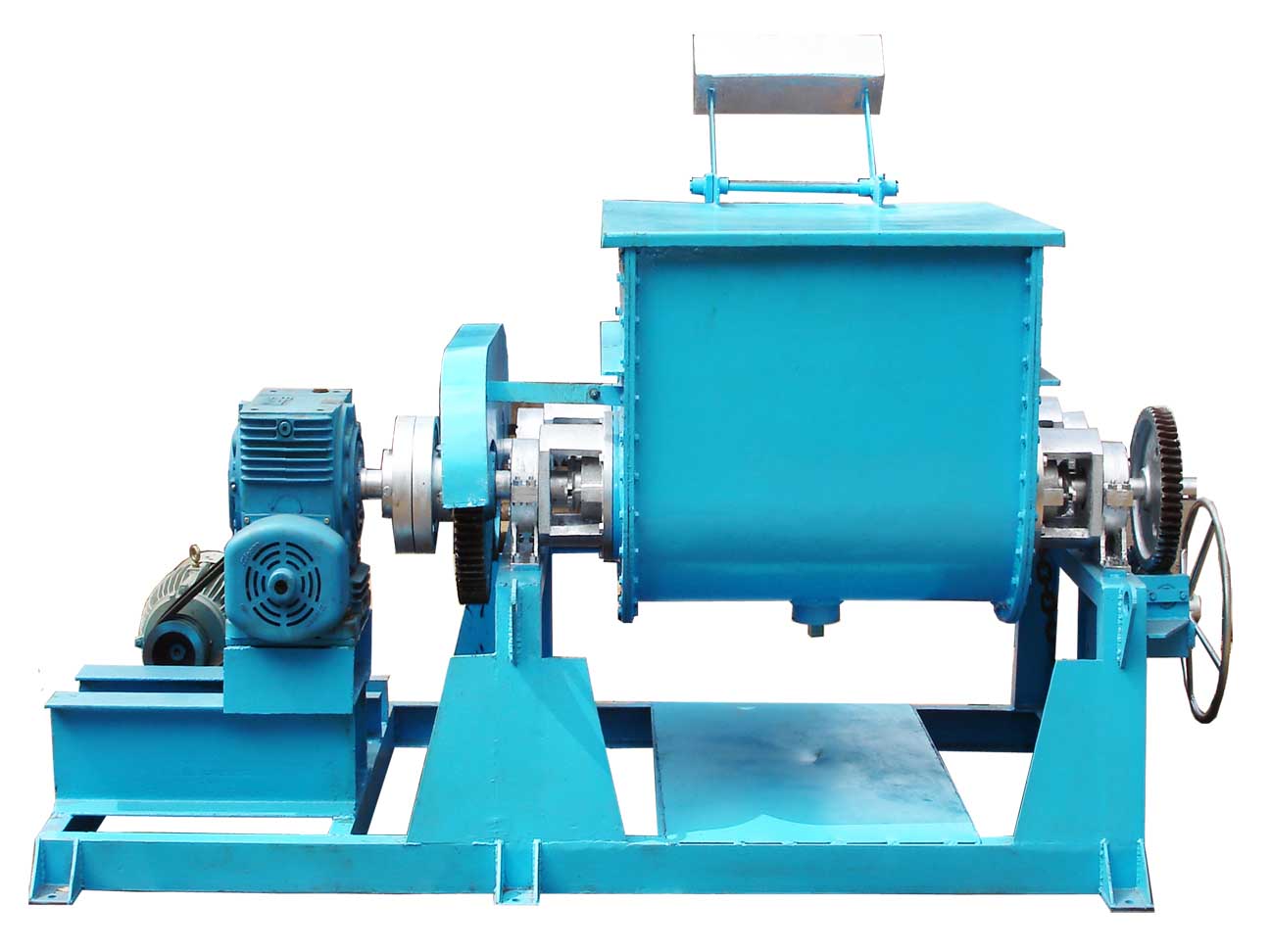

Sigma Mixer Machine

High viscose Mixer

Double Arm Kneader Mixers

All double arm kneader mixers are equipped with two mixing blades placed in a W-shaped horizontal trough. Various blade profiles have evolved, each of which is best suited for a particular type of application. The commonly used blade types are the sigma blade, masticator blade, shredder blade, naben (aka fishtail) blade, and spiral blade. The rotation of the blades is either tangential to each other or the blades may overlap within the trough. The blades rotate toward each other at the same or differential speeds. The blades pass the container walls and each other at close clearances (2-3 mm) resulting in homogenous mixing. The close clearances produce very high shearing action thereby reducing any large particles. These mixers produce a consistent particle size distribution without the need for additional high speed choppers. Homogenous mixing is achieved within 10 to 30 minutes. Mixing homogeneity upto 99% and better can be achieved using the double arm kneader mixers. These mixers and their variants (double arm kneader mixer extruders) are capable of handling material with viscosities as high as 10 million centipoises. The power consumption in double arm kneader mixer is very high compared to other types of mixers and can range from 45 to 75 kW/m3 of mix material. The sigma blade mixer is the most commonly used type of double arm kneader mixer, and is best suited for all round use.

Sigma Mixer machine

Sigma Blade Mixer In mixers handling very viscous materials, it is necessary to promote both lateral and transverse motion of the material. The geometry and profile of the sigma blade is designed such that the viscous mass of material is pulled, sheared, compressed, kneaded, and folded by the action of the blades against the walls of the mixer trough. The extent to which this happens depends on the action of the blades – tangential or overlapping and the ratio of the speed of rotation of the blades.The helix angle of the blade can be modified depending on the required shearing.

Operation of Sigma Blade Mixer

In operation, material is loaded through the top of the container to typically 40 to 65 percent of the mixer’s total volumetric capacity. The rotation of the blades is through heavy duty drive systems typically consisting of a motor, gearbox, couplings, and gears. The tip speed of the sigma mixer is generally limited to 60 metres per minute. Mixing may be carried out at ambient temperature or under controlled temperature conditions. The mixer troughs can be provided with jackets for circulation of hot or cold media to maintain the required temperature conditions within the mixer. The discharge of the material from the mixer container is either by tilting of the mixer container, bottom discharge valve (see figure 5), or through an extruder / screw located in the lower portion between the two trough compartments. The mixer may be equipped with any one of these discharge arrangements. The tilting discharge arrangement is most common. The tilting arrangement of the container may be designed for manual operation or may be mechanized using motorized or hydraulic arrangement.

Operation

In operation, material is loaded through the top of the container to typically 40 to 65 percent of the mixer’s total volumetric capacity. The rotation of the blades is through heavy duty drive systems typically consisting of a motor, gearbox, couplings, and gears. The tip speed of the sigma mixer is generally limited to 60 metres per minute. Mixing may be carried out at ambient temperature or under controlled temperature conditions. The mixer troughs can be provided with jackets for circulation of hot or cold media to maintain the required temperature conditions within the mixer. The discharge of the material from the mixer container is either by tilting of the mixer container (see figure 4), bottom discharge valve (see figure 5), or through an extruder / screw located in the lower portion between the two trough compartments (see figure 6).The mixer may be equipped with any one of these discharge arrangements.

The tilting discharge arrangement is most common. The tilting arrangement of the container may be designed for manual operation or may be mechanized using motorized or hydraulic arrangement.

Applications of the Sigma Mixer

The sigma mixer is the best suited mixer for pasty, sticky, and gritty slurries with high viscosities. The following are some of the commonly used products that are mixed in the sigma mixer.

- Adhesives

- Biscuit dough

- Butyl rubber

- Carbon pastes

- Ceramics

- Chemicals

- Chewing gum

- Crayon and pencil lead

Products We Offer

- All

- App

- Pharma Machinery

- Chemical Machinery

- Card

- Liquid section

- Granulation section

- Web

Our Products

We have vast range of Product portfolio like Pharmaceutical Machinery, Chemical Machinery, API and Bulk Drug Manufacturing Plant.

Sparkler Filter Press

Zero Hold up Sparkler filter press

Sparkler Filter Press

Zero Hold up Sparkler filter press

Sparkler Filter Press

Zero Hold up Sparkler filter press

Sparkler Filter Press

Zero Hold up Sparkler filter press

Sparkler Filter Press

Zero Hold up Sparkler filter press

Sparkler Filter Press

Zero Hold up Sparkler filter press

Sparkler Filter Press

Zero Hold up Sparkler filter press